Contact Email:

S.W.Boyd@soton.ac.uk

Description:

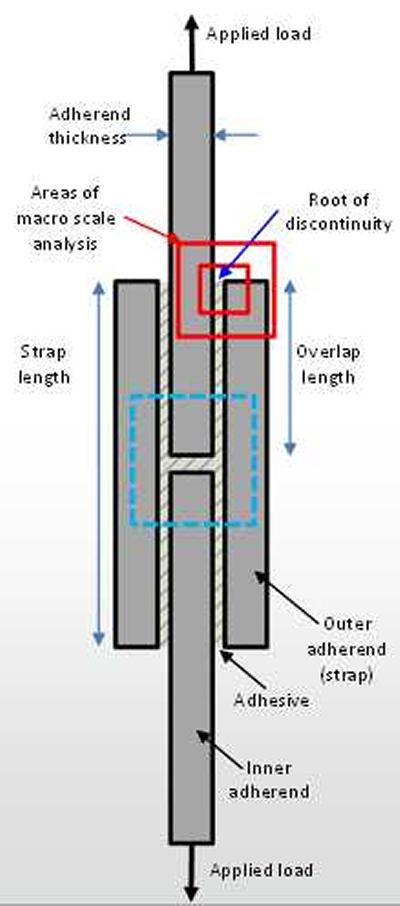

Adhesively bonded joints have been the subject of research for many years. Experimental studies, mathematical solutions and Finite Element Analyses have all been undertaken in an effort to establish their performance. In most cases the fundamental aim is to examine the stress in the joint due to structural loading but also methods of predicting failure. These experimental and numerical studies have been used in an effort to improve the design of adhesively bonded joints.

The introduction of composite materials into adhesively bonded joints increases the complexity of the predictive techniques and modes of failure. The use of Finite Element Analysis allows detailed examination of stresses and strains in the joint. However, these methods are based on assumptions. Experimental data is required to verify their results. It is this aspect of the subject that is most challenging.

The first stage in this research is the development of an experimental technique that enables a close examination of the adhesive joint, ideally providing full-field data-rich stress and strain data whilst the joint is subjected to load. Digital Image Correlation (DIC) and Thermoelastic Stress Analysis (TSA) are two techniques available at the University of Southampton and are the subject of continuing research and development. The research conducted in this project investigated their use at high magnification to determine the stress and strain in an adhesively bonded joint under load. The main thrust of research was in the examination of the influence of the random speckle pattern used in DIC at high magnification and the development of a method for assessing speckle pattern quality.

Once the experimental technique had been developed it was used to examine adhesively bonded joints under a variety of loading scenarios. The testing created a level of detailed data never seen before for adhesively bonded joints. The data can be used qualitatively to examine areas of high stress and strain concentration, but also quantitatively to assess the onset of failure and the failure mechanisms. This was conducted under static loads and with joints subjected to a high-speed loading. In the case of high-speed loading, high-speed digital cameras were employed to capture the failure of the adhesive joint. Data from both Digital Image Correlation and thermoelastic stress analysis can be used to validate numerical models of adhesively bonded joints.